Click to visit our contact page, you can send us a message.

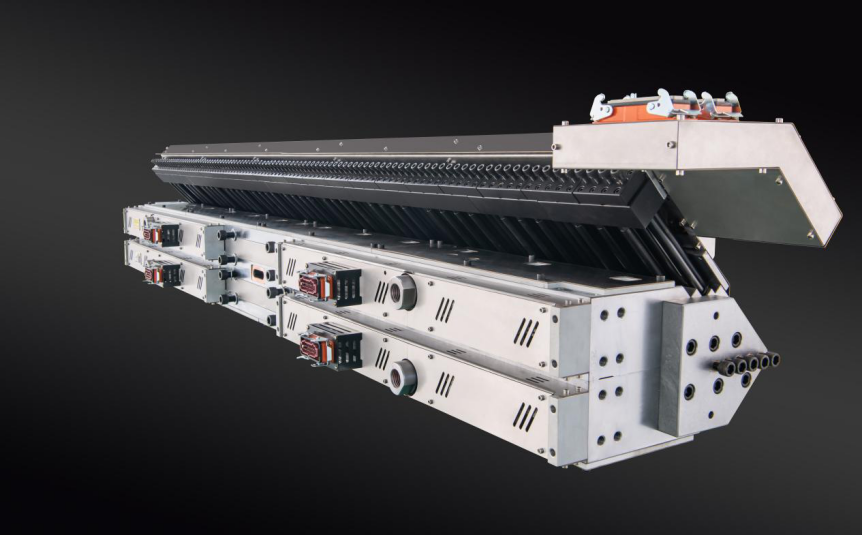

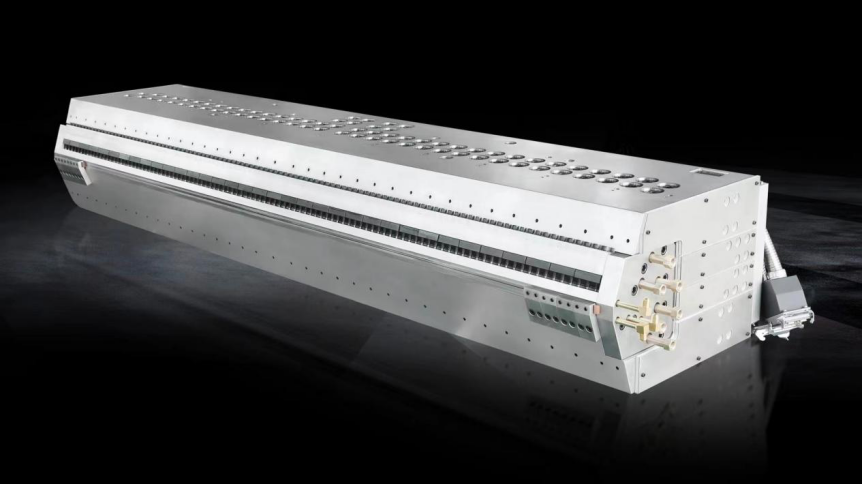

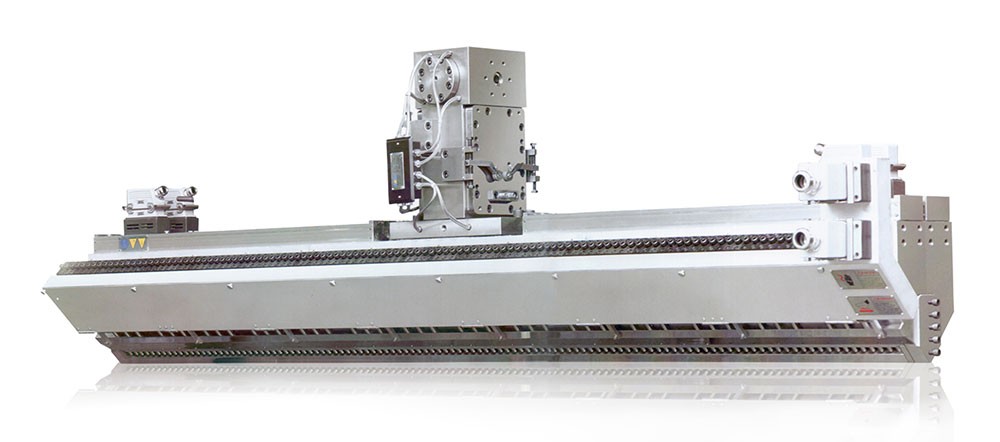

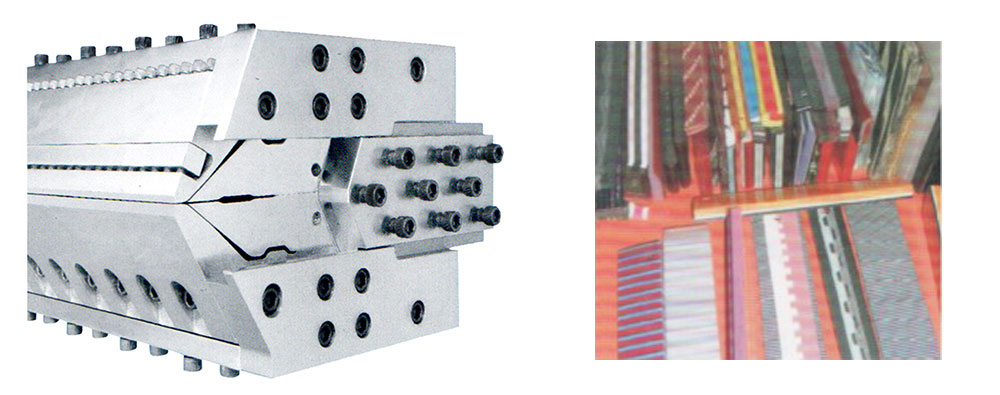

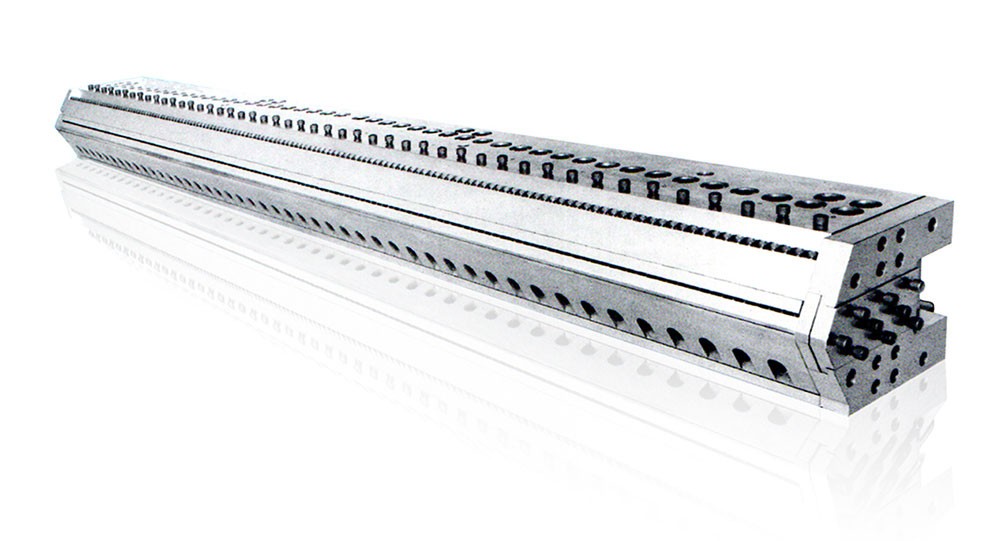

Contact usThis die adopts a long V-drop-shaped runner, triangular flow splitting technology and a special steady flow structure. Effectively improve the composite precision of each composite layer and reduce the production of "M" and "W" shapes in the extrusion process. The upper die lip adopts a push-out manual fine-tuning and automatic fine-tuning integrated die lip, which is called One-piece mold lip, the manual adjustment range is ±1mm, the automatic adjustment range is ±300μm; the automatic die lip adjustment control part we use is currently very advanced fully closed loop control system and self-use thickness measurement. The system enables the thickness accuracy of the product to be within ±2%. The on-line thickness gauge can continuously and automatically detect and scan the horizontal direction at a high frequency, which can accurately display the thickness tolerance of the product in real time. The detection data of the online thickness gauge is processed by a computer program and fed to a special die lip thermal expansion adjustment bolt to realize automatic fine-tuning of the opening thickness of the die lip, and quickly and effectively control the product accuracy. In addition, our die head has good scalability, and can be equipped with "internal plug-type width adjustment device" or "external plug-type width adjustment device" with device to remove thick side according to customer needs, to better meet the needs customers’ need to produce a variety of wide-format products to achieve more economical and more efficient production.

This type of die is suitable for the production of single-layer or multi-layer films such as CPP, PE, EVA, PVC, PET, PVB, and PA with a thickness of 0.06-0.18mm under 5000mm.

We use melt rheology analysis technology for each set of molds, combined with computer engineering technology to master the uniform, stable and reasonable design of the extrusion rheology of the raw materials in the mold. According to the actual requirements, the mold can be adjusted quickly and effectively to produce high-quality and qualified products in the shortest time.

This die head adopts an extended V-droplet flow channel, triangular shunt technology and a special flow stabilization structure. Effectively improve the composite precision of each composite layer and reduce the generation of M-shaped and W-shaped materials during extrusion. The upper mold lip adopts the push-type manual fine adjustment + automatic fine adjustment-body-type mold lip, with a manual adjustment range of ± 1mm and an automatic adjustment range of ± 300um; the automatic mold lip adjustment control part uses the currently very advanced fully closed-loop control system and automatic thickness measurement. The system enables the thickness accuracy of the product to be within ± 2%, and the online thickness gauge automatically and continuously detects and scans at high frequencies. The thickness tolerance of the product can be displayed very accurately in real time. After processing the data from the online thickness gauge through a computer program, it feeds back to the special die lip expansion adjustment bolts to achieve automatic fine adjustment of the thickness of the opening of the die lip to quickly and effectively control the accuracy of the product. And our die has good expandability. We can choose "inside plug width adjustment device" or "outside plug width adjustment device" with thick-edged device according to customer's needs, which can better meet customers' production requirements. The possibility of wide products can realize more economical and more efficient production.

This type of die is suitable for production below 5000mm. CPP, PE, EVA, PVC, PET, PVB, PA and other single-layer or multi-layer films with a thickness of 0.06-0.18mm.

Each die adopts melt rheology analysis technique combined with computer engineering technology .According to the acutal requirement,you can effectibvely adjust the die and produce the high-qualified products,within the minimized ,by the balanced,stable and reasonable design fro the raw erials int he die extrusion rheological.

Add: 20 Maofeng Street, Xinqian Development Zone, Huangyan District, Taizhou City, Zhejiang Province, China

Tel: 0086-13957653333

Email: sale@jingcheng.net

Sales Manager:13634016666

Foreign Trade Manager:15067658888

FAX:0576-84907777